With a proven track record, NeoNickel continue to invest in the latest metal cutting and profiling technology and techniques, to keep them, literally, at the cutting edge of the industry. From this starting point, they can offer six key solutions to deliver everything from a single piece to a series of components…

-

- ****

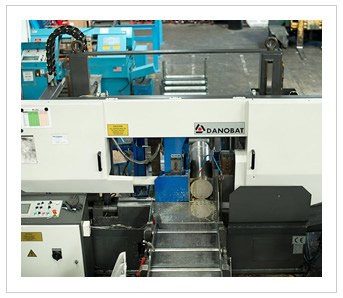

Bar Sawing – Our highly-skilled team continue to produce a wide range of high quality components that find uses in many industries, including chemical processing, oil and gas, aerospace, thermal processing and more. As well as delivering truly world-grade engineering results, they can use all types of materials from high-temperature nickel alloys to stainless steels.

Bar Sawing – Our highly-skilled team continue to produce a wide range of high quality components that find uses in many industries, including chemical processing, oil and gas, aerospace, thermal processing and more. As well as delivering truly world-grade engineering results, they can use all types of materials from high-temperature nickel alloys to stainless steels.

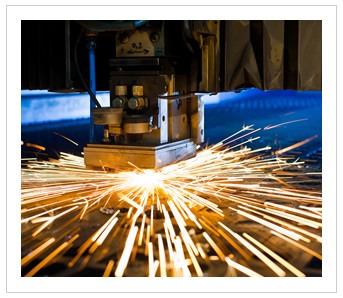

- - **[Laser Cutting](https://www.neonickel.com/processing/laser-cutting/ "Laser Cutting")** – Delivering unbeatable quality products exactly as promised has long been our standard practice. Nowhere more so than in this specialism. State-of-the-art laser cutting facilities are in place throughout their European operation The material is melted or vapourised, and gas is then used to clear molten material from the lasered area. It’s a highly-accurate, repeatable and consistent, high-detail process, which allows both speed of work and a low cost for parts.

As laser cutting isn’t affected by material hardness, high carbon can be cut as effectively as mild steels.

- - **[Waterjet Cutting](https://www.neonickel.com/processing/waterjet-cutting/ "Waterjet Cutting")** – Offering better value than some other options, this process can cut virtually any material, to a wide selection of thicknesses, and to almost any shape. Using the latest waterjet cutting facilities allows the expert teams at NeoNickel to meet the most precise of specifications, whether you are requiring a one-off, or need to have a large batch production run completed.

Over the last three decades and more, the number of world-class customers and industry sectors who choose to work with NeoNickel has just grown and grown. Think Boeing and Rolls Royce, nuclear power plant cooling systems and heat exchangers on oil rigs, or a range of medical alloys.

One of our company’s key strengths is our ability to deal with any size of project, whilst working to tight deadlines, and whether for an established giant or a business starting to make its way in the world. Contact us to learn more about our metal processing techniques and how we can help you.

Bar Sawing – Our highly-skilled team continue to produce a wide range of high quality components that find uses in many industries, including chemical processing, oil and gas, aerospace, thermal processing and more. As well as delivering truly world-grade engineering results, they can use all types of materials from high-temperature nickel alloys to stainless steels.

Bar Sawing – Our highly-skilled team continue to produce a wide range of high quality components that find uses in many industries, including chemical processing, oil and gas, aerospace, thermal processing and more. As well as delivering truly world-grade engineering results, they can use all types of materials from high-temperature nickel alloys to stainless steels.