Alloy 600 vs Alloy 625 – Which Is Better for High-Temperature Applications?

When selecting the right material for extreme environments, understanding the differences between high-performance alloys is crucial. Two commonly used grades, Alloy 600 and Alloy 625, are both nickel-based superalloys known for their exceptional resistance to heat and corrosion.

But when it comes to Alloy 600 vs Alloy 625, which one offers better performance in high-temperature applications?

In this detailed comparison, we’ll explore:

- How Alloy 600 and Alloy 625 perform under thermal stress

- Their mechanical and corrosion-resistant properties

- Typical industrial use cases

- Key considerations to help you choose the right alloy for your needs

What Are Alloy 600 and Alloy 625?

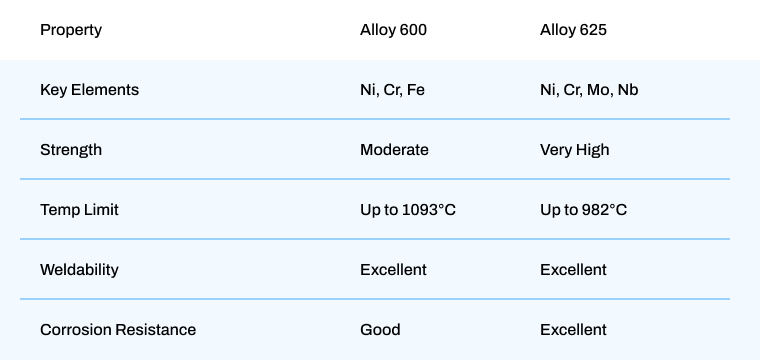

Alloy 600 (UNS N06600) A nickel-chromium-iron alloy designed for resistance to heat and corrosion. It is commonly used in high-temperature oxidation environments and applications exposed to caustic solutions.

Alloy 625 (UNS N06625) A nickel-chromium-molybdenum-niobium alloy offering excellent strength and superior resistance to a wide range of severely corrosive environments. Alloy 625 is particularly known for its performance under high stress and heat.

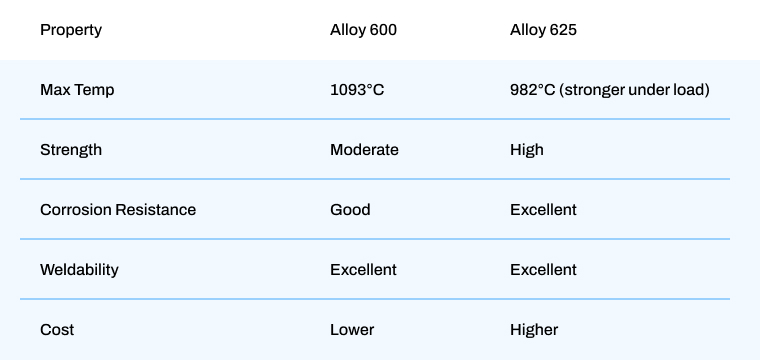

High-Temperature Performance

Alloy 600

- Performs well up to 1093°C

- Resists oxidation, carburisation, and thermal fatigue

- Ideal for furnace components and thermal processing

Alloy 625

- Offers high tensile strength up to 982°C

- Maintains mechanical integrity under sustained thermal and mechanical stress

- Common in aerospace ducts, chemical reactors, and high-pressure systems

Conclusion: If your priority is pure heat resistance, Alloy 600 may suffice. But for high heat with mechanical load, Alloy 625 is the stronger option.

Corrosion Resistance

Alloy 600

- Good resistance in oxidising and reducing environments

- Performs in environments with chlorides, ammonia, and organic acids

- Suitable for nuclear steam generators and alkaline processes

Alloy 625

- Superior pitting, crevice, and stress corrosion cracking resistance

- Performs well in marine, offshore, acidic, and sour gas environments

- Molybdenum enhances performance in chloride and acidic conditions

Conclusion: Alloy 625 offers greater protection in aggressive or salt-laden environments.

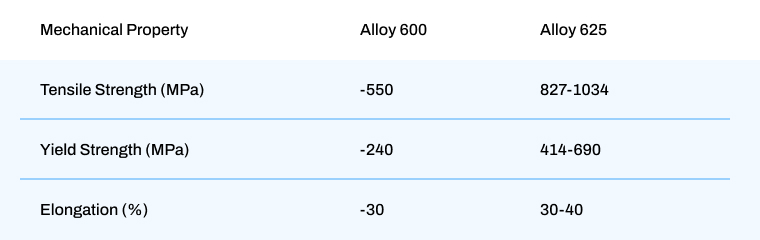

Mechanical Strength Comparison

Conclusion: Alloy 625 is significantly stronger, making it suitable for pressure vessels and load-bearing components.

Weldability & Fabrication

Both alloys are:

- Highly weldable with standard methods (TIG, MIG, SMAW)

- Capable of being cold-formed and machined

- Not prone to post-weld cracking

Note: Alloy 625’s higher strength may increase tooling wear during machining.

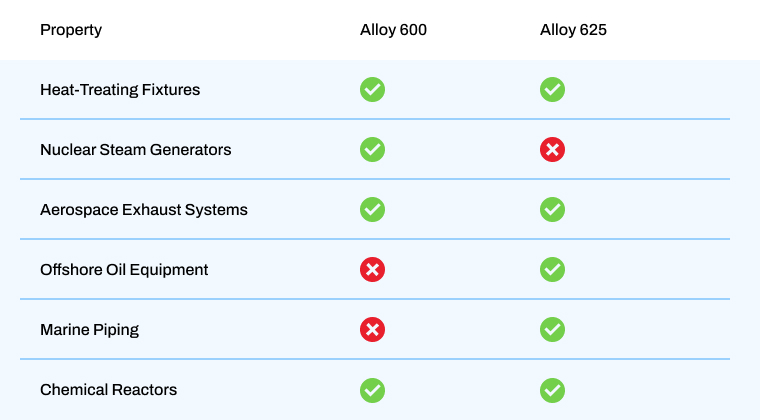

Typical Applications

Cost and Availability

- Alloy 600 is generally more cost-effective and readily available

- Alloy 625 carries a higher price point, but offers greater longevity in aggressive environments

Selection Tip: If your project is budget-sensitive and operates in high heat, choose Alloy 600. If you're investing in longevity and corrosion resistance, Alloy 625 may justify the additional cost.

Alloy 600 vs Alloy 625: Summary

Bottom Line:

- Choose Alloy 600 for general high-heat use where cost and availability matter

- Choose Alloy 625 when strength and corrosion resistance are critical, especially in marine, offshore, and chemically aggressive settings

Further Resources

- Alloy 600 Product Page

- Alloy 625 Product Page

- What is Alloy 600? Applications, Composition & Properties Explained

- Alloy 625 Explained: A Technical Breakdown of Composition, Properties & Performance

Talk to a Specialist

Still unsure which alloy is right for your application? Contact our team of alloy experts at NeoNickel to discuss your project and receive tailored material recommendations.