What is Alloy 600? Applications, Composition & Properties Explained

Alloy 600, also known as Inconel® 600, UNS N06600, or W.Nr. 2.4816, is a high‑performance nickel‑chromium‑iron alloy engineered to withstand extreme heat, oxidation, and corrosion. It’s widely used in industries such as chemical processing, aerospace, nuclear power generation, and thermal treatment, where mechanical strength and stability under pressure are critical.

In this in‑depth guide, we’ll explore:

- Where Alloy 600 is used and why it remains a preferred material in high‑performance industries

- Its key mechanical and thermal properties and how they support demanding applications

- Its chemical composition and what that means in practical engineering terms

- Important design considerations, limitations, and how to select the right form for your specific application, whether it’s pipe, plate, tube or bar

With a balance of durability, versatility and resistance to corrosive environments, Alloy 600 continues to be one of the most reliable materials for engineers and manufacturers operating in extreme conditions.

What Is Alloy 600 Made Of?

Alloy 600 is a solid solution-strengthened alloy primarily composed of nickel (Ni), chromium (Cr), and iron (Fe). Its balance of elements makes it resistant to oxidation, carburisation, and high-temperature corrosion.

Typical chemical composition:

- Nickel (Ni): ~72% – Provides excellent resistance to heat and corrosion

- Chromium (Cr): 14–17% – Enhances oxidation and scaling resistance

- Iron (Fe): 6–10% – Contributes to structural strength

- Others: Small quantities of manganese, copper, silicon, and carbon

These elements work together to provide Alloy 600 with superior resistance to:

- Chloride-ion stress corrosion cracking

- Oxidation in high-temperature environments

- Carburising and nitriding atmospheres

- Sulphur-containing gases (in non-red-heat conditions)

When and Why to Specify Alloy 600

Alloy 600 is not a general-purpose material. It’s chosen specifically for harsh environments where conventional stainless steels or lower-grade nickel alloys fail. Engineers choose Alloy 600 for its:

- Temperature stability: Up to 1150°C in oxidising atmospheres

- Corrosion resistance: Especially in chloride-rich, sulphur-containing or caustic environments

- Stress integrity: Resistance to stress corrosion cracking and thermal fatigue

Corrosion Mechanisms & How Alloy 600 Performs

What sets Alloy 600 apart is its ability to resist multiple forms of corrosion and degradation:

- Chloride Stress Corrosion Cracking (CSCC): The high nickel content prevents crack initiation in chloride-rich settings.

- Oxidation: Forms a stable oxide layer that resists flaking and further oxidation up to 1093°C.

- Carburisation & nitriding: Performs well in furnace atmospheres containing carbon or nitrogen.

- Sulphur-containing gases: Can withstand mild sulphur exposure but is not suitable for use at red heat with sulphur present.

These characteristics make it ideal for harsh chemical and high-temperature industrial applications.

Industrial Applications: Where Alloy 600 Is Used

Because of its unique blend of properties, Alloy 600 is used extensively in high-performance applications across multiple industries. Here's a breakdown by sector:

1. Chemical Processing

Alloy 600 performs exceptionally well in corrosive chemical environments. Its resistance to oxidising and reducing agents, chlorine, alkalis, and organic acids makes it suitable for:

- Evaporator tubes and heaters

- Bubble towers

- Alkali processing equipment

- Pumps, valves, and reaction vessels

- Pulp and paper bleach plant hardware

2. Aerospace

In aerospace, Alloy 600 offers high strength and oxidation resistance at elevated temperatures. It’s commonly used in:

- Jet engine components

- Exhaust liners

- Combustion-can liners

- Afterburner parts

- Diffuser assemblies

Its structural integrity at high temperatures ensures performance in both airframes and propulsion systems.

3. Power Generation and Nuclear

Its resistance to corrosive steam and chloride stress cracking makes Alloy 600 a strong candidate in nuclear and fossil-fuel power plants. It’s used in:

- Steam generator tubing

- Control rod components

- Heat exchangers

- Reactor vessels and support grids

Alloy 600 also resists scaling and embrittlement over long-term service in high-heat environments.

4. Heat Treatment and Thermal Processing

Alloy 600 maintains strength and dimensional stability at high temperatures. It’s often used in:

- Furnace muffles

- Retorts and baskets

- Heat-treating fixtures

- Roller hearths

- Annealing boxes

Its resistance to carburisation and nitriding atmospheres is critical in thermal cycling applications.

5. Marine & Offshore

Due to its resistance to chloride-induced corrosion and biofouling, Alloy 600 is suitable for:

- Heat exchangers exposed to seawater

- Offshore process equipment

- Pumps and valves for brine and salt environments

Fabrication, Welding & Forming: What You Need to Know

Alloy 600 is considered highly workable compared to other nickel alloys, but there are best practices that ensure its performance:

Welding

- Compatible with standard TIG, MIG and submerged arc welding

- No post-weld heat treatment required to maintain corrosion resistance

- Low risk of weld cracking when proper filler metals are used (e.g., ENiCrFe-3)

Stress Relieving

- Recommended after cold working or welding: 982–1010°C for 1 hour

- Enhances resistance to alkali-induced stress corrosion cracking

Forming & Machining

- Easily cold-formed with standard methods

- Hot working should be done between 870–1180°C

- Can be machined using conventional tools, though slower feed rates may be necessary

Limitations

- Not suitable for sulphur-rich atmospheres at red heat

- Can experience caustic cracking in hot, concentrated alkalis without proper stress relief

Choosing the Right Form of Alloy 600

Selecting the right product form is critical for performance and durability. NeoNickel supplies Alloy 600 in a variety of stock forms:

Alloy 600 Pipe Ideal for heat exchangers and process piping, especially in caustic and oxidising environments.

Alloy 600 Tube Preferred in chemical and nuclear applications where small diameter tubing is exposed to high heat or stress.

Alloy 600 Plate Commonly used in heat treatment systems, reactor linings, and furnace fabrication.

Alloy 600 Round Bar Used for machined components, shafts, fasteners and structural applications under stress.

Need a specific form? Visit our Alloy 600 product page to check availability and request a quote.

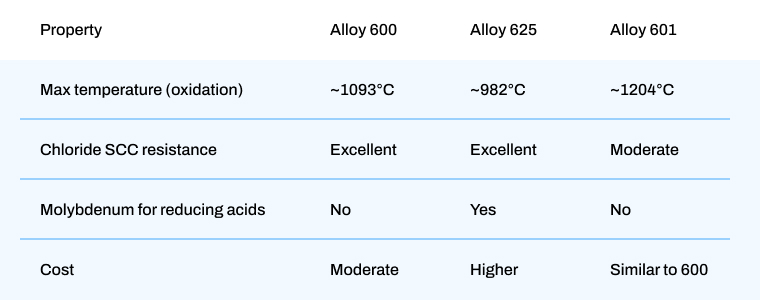

Alloy 600 vs Other Alloys: Which Is Right for You?

Key takeaways: Choose Alloy 625 for greater strength and acid resistance. Opt for Alloy 601 for slightly higher oxidation resistance but lower general corrosion protection.

Summary: Is Alloy 600 Right for Your Application?

Alloy 600 is an ideal material when your engineering environment demands:

- Resistance to chloride stress corrosion or thermal cycling

- High-temperature mechanical integrity

- Fabrication flexibility and post-weld performance

If you're working on equipment for chemical processing, power generation, or high-temperature furnace systems, Alloy 600 remains one of the most reliable solutions available.

Ready to specify Alloy 600 for your next project?

Visit our Alloy 600 product page to explore available forms including pipe, tube, plate and round bar. You'll find full technical specifications, downloadable datasheets, and the option to request a quote. Whether you're working in chemical processing, thermal treatment or power generation, we’re here to help you source the right alloyt.