Pitting Corrosion

Are you seeing requirements calling for the passivation of stainless steels?

Stainless steels, even the least alloyed, will passivate immediately upon exposure to air. This is basic physical chemistry and the rapid oxidation of Chromium is the fundamental reason stainless steels are “stainless”.

Typically the requirement arises relative to fabrication issues such as the removal of heat tint from welding or simple Iron contamination from forming and fabrication. Anything that remains on the surface of the stainless steel that can hinder the formation of the oxide film should be removed. This includes machining lubricants, grease, dirt, Iron contamination from accidental or planned contact and particulates from grinding.

Typically the requirement arises relative to fabrication issues such as the removal of heat tint from welding or simple Iron contamination from forming and fabrication. Anything that remains on the surface of the stainless steel that can hinder the formation of the oxide film should be removed. This includes machining lubricants, grease, dirt, Iron contamination from accidental or planned contact and particulates from grinding.

In the simplest case, cleaning the surface to remove oils and particulate is sufficient. Cleaning is facilitated by using a mild oxidising solution such as citric acid or dilute nitric acid. ASTM Specification A967 is a useful document for performing and evaluating passivation treatments. The citric acid based solutions are not typically strong enough to completely remove heat tint. Nitric acid is a stronger oxidant and is more effective at removing heat tint and free Iron. The use of nitric acid and other stronger chemicals for pickling are covered in ASTM Practice A380. These stronger solutions are necessary to remove the oxides and scales from a highly alloyed material such as AL-6XN® or ZERON® 100. Commercial pickling pastes are also effective in removing heat tint.

Removal of the heavier oxides that are formed during annealing or other heat treating operations typically require one of the stronger solutions described in A380. The formation of these oxide scales (and to a lesser extent, heat tint from welding) can result in a slightly alloy depleted surface layer. This layer can be slightly less corrosion resistant than the base metal and for the most critical services it is important to properly pickle the metal surface then remove this depleted layer.

Removal of the heavier oxides that are formed during annealing or other heat treating operations typically require one of the stronger solutions described in A380. The formation of these oxide scales (and to a lesser extent, heat tint from welding) can result in a slightly alloy depleted surface layer. This layer can be slightly less corrosion resistant than the base metal and for the most critical services it is important to properly pickle the metal surface then remove this depleted layer.

There is an environmental handling advantage in using the milder citric acid based products. It may be desirable to use mechanical means to remove heat tint (i.e. grinding, polishing, shot blasting) and then use citric acid to remove free Iron and particulate. When using any acid or base to passivate and clean, the part should be thoroughly rinsed with potable water.a

What is pitting corrosion and how does it happen?

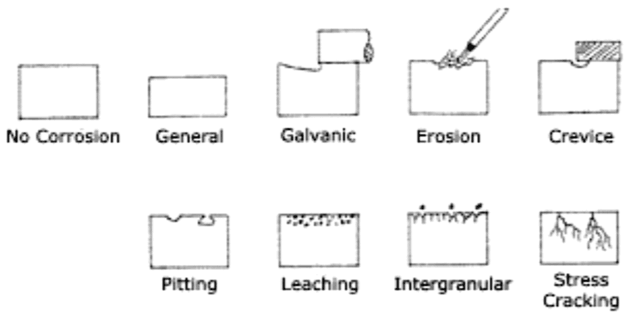

Pitting corrosion is in itself a corrosion mechanism, but is also a form of corrosion often associated with other types of corrosion mechanisms. It is characterised by a highly localised loss of metal. In the extreme case, it can appear as a deep, tiny hole in an otherwise unaffected surface. The adjacent figure illustrates the nature of pitting and other forms of corrosion.

The initiation of a pit is associated with the breakdown of the protective film on the metal surface. In cases where pit depths increase rapidly, the environment is usually such that no repair or re-passivation of the protective layer can be accomplished. For other instances where many shallow pits form, the environment is usually one where re-passivation of the damaged film can be made, but initiation of new sites is occurring on a regular basis.

The localised nature of pitting attack can be associated with component geometry, the mechanics of the corrosion process, or with imperfections in the material itself. The growth of pits, once initiated, is closely related to another corrosion mechanism, crevice corrosion.

| Alloy | PRE |

|---|---|

| 304L | 19.5 |

| 316L | 23.5 |

| 2205 | 35.0 |

In stainless and Nickel alloys, Chloride ions are particularly efficient at breaking down the passive protective film. Experience has shown that alloy additions of Chromium and Molybdenum are particularly beneficial in increasing resistance to pitting attack.

| ZERON® 100 | AL-6XN® | Alloy 625 |

|---|---|---|

| 40.1 | 43.2 | 49.5 |

Laboratory testing has shown a correlation that has been identified as the Pitting Resistance Equivalent (PRE) where PRE = %Cr + 3.3 * %Mo + 16 * %N. Increasing resistance to pitting (and crevice corrosion) is found as the PRE increases. Typical PRE’s for several alloys are shown in the table.

The Technical Association of the Pulp and Paper Industry (TAPPI) has an excellent publication that describes how to apply various pickling and passivating techniques depending on the type of equipment and service needs. It is named TIP 0402-35 and is available at the www.TAPPI.org website.

Technical support

Our team of metallurgists can provide you with any technical support that you may require. Please send your technical questions to [email protected]. Alternatively, if you’d like to find out more about our services, please visit our Technical Services page.