Applications of Inconel Alloy X in Aerospace, Power & Industrial Markets

In this guide, we explore:

- Key industries where Inconel Alloy X is used, including aerospace, power generation, and industrial furnaces.

- Why Alloy X is often specified over other high‑temperature alloys.

- Real-world example use‑cases.

- Helpful guidance for specifiers and engineers.

If you’d like technical specifications or to check availability, visit our Alloy X product page.

Why Alloy X is Widely Specified

Alloy X (UNS N06002 / W.Nr. 2.4665) is a nickel‑chromium‑iron‑molybdenum superalloy engineered for strength, fabricability and oxidation resistance under extreme temperatures and demanding atmospheres.

What sets it apart:

- High-temperature strength & stability: Alloy X retains mechanical integrity at elevated temperatures, making it ideal for sustained heat exposure.

- Oxidation resistance: Offers strong resistance to oxidation in hot, oxidising atmospheres, which protects components from scaling and degradation.

- Resistance to carburising & reducing atmospheres: Performs well in furnaces and combustion chambers where carburising or reducing gases exist.

- Fabricability & weldability: It can be hot or cold worked, welded via conventional methods, and annealed as required, giving flexibility for complex parts.

- Versatile product forms: Available as plate, sheet, bar, wire, enabling different component types from structural to thin‑wall ducts.

Because of this balanced performance, Alloy X is often preferred over simpler high‑temp stainless steels or pure nickel alloys when higher thermal and chemical demands are expected.

Aerospace & Turbine Engine Applications

Typical Uses:

- Combustion can liners and combustor parts

- Afterburner components, turbine exhaust ducts and flame-holders

- Transition ducts, tailpipes and exhaust frames

- Aircraft environmental control system (ECS) ducting and hot‑gas paths

Why Alloy X Is a Top Choice

Gas turbine engines and jet propulsion systems operate under extreme thermal cycling, exposure to hot combustion gases, carburising or oxidising atmospheres, and mechanical stress. Alloy X’s alloy chemistry, including nickel‑chromium‑molybdenum base, delivers a combination of high-temperature strength, oxidation resistance, and resistance to carburising/reducing environments.

Unlike many standard stainless steels or lower‑grade nickel alloys, Alloy X handles the thermal shock, cyclic stress and environmental attack typical of jet engines and afterburners. Its fabricability and weldability also facilitate the complex geometries and welded assemblies often required in aerospace components.

Power Generation & Gas Turbine Applications

Typical Uses:

- Turbine exhaust ducts and transition pieces

- Heat Recovery Steam Generator (HRSG) components

- Combustion systems for land‑based gas turbines

- Industrial furnace linings, reformer components, and heat-treatment equipment

Why Alloy X Works Well

In power plants and industrial furnaces, components face constant high heat, oxidising or carburising atmospheres, possible sulphur-containing gases, and long duty cycles. Alloy X’s high-temperature strength and oxidation resistance make it suitable for these harsh conditions.

Compared to austenitic or ferritic steels, Alloy X provides superior thermal creep resistance and longevity. Compared to pure nickel or simpler alloys, Alloy X’s balanced alloying (Cr, Mo, Fe) gives better resistance to environmental attack without sacrificing strength — delivering a greater lifespan under continuous service. This makes Alloy X a go‑to material when reliability, minimised maintenance and long service life are critical.

Industrial Furnace & Heat-Treating Applications

Typical Uses:

- Furnace muffles, retorts, hearth trays and baskets

- Heat-treatment chambers and internal linings

- Petroleum cracking, pyrolysis and chemical high-temp vessels

- High‑temperature processing equipment in the chemical and material industries

Why Alloy X Is Well-Suited

Furnace environments often combine high temperature, presence of carburising or reducing gases, thermal cycling, and potential corrosive chemicals or sulphur compounds. Alloy X’s resistance to oxidation, carburisation and thermal fatigue — plus its fabricability — make it a reliable choice for long-term furnace service.

Specifically, its ability to maintain strength and resist surface degradation over hundreds or thousands of hours reduces maintenance, downtime and total cost of ownership.

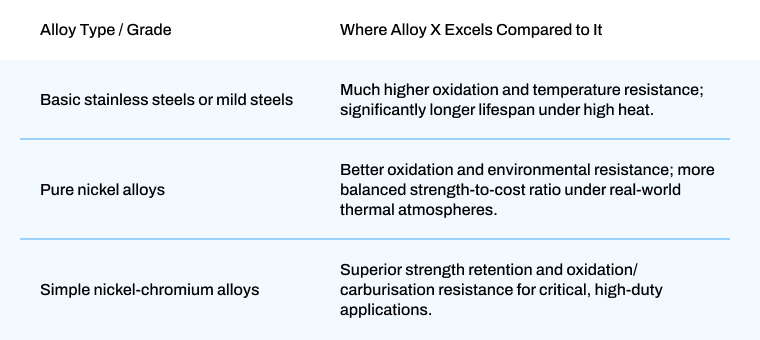

Why Engineers Often Prefer Alloy X Over Other High‑Temperature Alloys

Alloy X’s strength, oxidation resistance, environmental durability, and fabrication flexibility combine to offer a balanced solution for high‑temperature, harsh‑environment applications, which is why it remains a top-tier choice in aerospace, power and industrial sectors.

Practical Considerations When Specifying Alloy X~~Strikethrough~~

- Weldability: Alloy X welds readily via TIG, MIG, SMAW and similar processes. After heavy forming or welding, solution-annealing at ~1177 °C (then rapid air-cool) is recommended to restore optimum properties.

- Temperature limits: While Alloy X exhibits excellent oxidation resistance up to ~1090 °C, exposure beyond ~1200 °C (2200 °F) may risk rapid oxidation. Designers should confirm service temperatures and environment before specifying.

- Atmosphere conditions: For carburising, reducing, sulphur or mixed-gas atmospheres, Alloy X performs well, but confirmation via actual process conditions and testing is recommended.

- Fabrication vs performance: Alloy X’s mechanical properties, especially under cyclic stress or long-term heat, depend on correct heat-treatment and fabrication. Always request full mill certification and heat‑treatment records for critical parts.

Ready to Source Alloy X for Your Project?

Whether you’re building turbine exhaust systems, industrial furnaces, aerospace combustion components, or high-temperature processing equipment, Alloy X is a trusted, proven material.

Visit our Alloy X product page to view available product forms, check specifications, and request a quote today.