Alloy L605 vs Alloy 188 – What’s the Difference & Which Should You Use?

When selecting a high‑performance cobalt alloy for demanding applications such as aerospace components, gas turbines or high‑temperature furnace parts, two of the most widely considered options are Alloy L605 and Alloy 188. Though both are cobalt‑based superalloys with excellent strength at elevated temperatures, they differ in composition, performance, oxidation resistance and ideal use cases.

This comparison is designed to help engineers, specifiers and procurement professionals understand the differences between these two materials and make informed decisions, without competing with the dedicated product pages at NeoNickel. For detailed specifications and product availability, visit the Alloy L605/25 and Alloy 188 product pages.

What Are Alloy L605 and Alloy 188?

Alloy L605

Alloy L605 (UNS R30605) is a cobalt‑chromium‑nickel‑tungsten superalloy known for its exceptional strength, oxidation resistance and wear/galling resistance at elevated temperatures. Sometimes referred to as Haynes 25, L605 has been widely used in aerospace, gas turbine and industrial high‑temperature environments.

Key characteristics:

- Primary base: Cobalt with chromium, nickel and tungsten

- Oxidation resistance up to ~1093°C (2000°F)

- Very good wear and galling resistance

- Strong in applications with sulphidation environments

Alloy 188

Alloy 188 (UNS R30188) is a cobalt‑chromium‑nickel alloy with added tungsten and rare earth elements that enhance oxidation resistance and high temperature strength. It was developed for environments where long‑term exposure to oxidising gases, sulphate deposits and thermal cycling is expected.

Key characteristics:

- Primary base: Cobalt with chromium, nickel and tungsten

- Excellent oxidation and hot corrosion resistance

- Good ductility after prolonged high‑temperature exposure

- Highly suited to aerospace hot sections and gas turbines

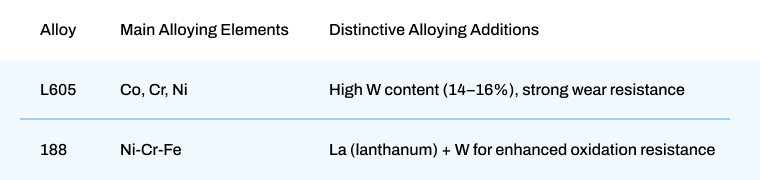

Alloy L605 vs Alloy 188 — Composition Comparison

Alloy L605 Composition (approx %):

- Cobalt: Balance

- Chromium: 19–21%

- Nickel: 9–11%

- Tungsten: 14–16%

- Carbon: 0.05–0.15% Others (Fe, Mn, Si, P, S): controlled low levels

Alloy 188 Composition (approx %):

- Cobalt: Balance

- Chromium: 20–24%

- Nickel: 20–24%

- Tungsten: 13–16%

- Lanthanum: 0.02–0.12%

- Carbon: 0.05–0.15%

The addition of lanthanum in Alloy 188 helps improve the alloy’s oxide scale adherence and hot corrosion resistance, especially in sulphur‑containing environments.

Mechanical Properties Comparison

Both alloys maintain impressive tensile and yield strength at elevated temperatures, but with different emphasis:

Alloy L605 typically exhibits higher tensile and yield strengths under short‑term loading at elevated temperatures, while Alloy 188 retains ductility more consistently after prolonged high‑temperature exposure.

High‑Temperature Oxidation & Corrosion Performance

Alloy L605

- Resists oxidation in air up to around 1093°C

- Performs well in carburising and sulphidation environments

- Known for wear and galling resistance under sliding contact

Alloy 188

- Designed for extended exposure to oxidising combustion gases

- Exceptional resistance to sulphate‑deposit hot corrosion

- Maintains oxidation resistance even after many thermal cycles

Summary: Both alloys handle high heat well, but Alloy 188’s composition (especially the lanthanum addition) gives it a slight edge in long‑term oxidation and hot corrosion resistance.

Fabrication, Weldability & Formability

Both alloys are workable and weldable, but there are important distinctions:

Alloy L605

- Weldable using GTAW (TIG), GMAW (MIG), SMAW or electron beam

- Welding practices should minimise restraint, use low interpass temperatures, and allow rapid cooling

- Best ductility achieved after annealing at 1176–1232°C

Alloy 188

- Also weldable using TIG, MIG or electron beam methods

- Maintains good ductility after welding

- Fabrication is similar to other cobalt alloys but requires attention to heat input due to thermal stability needs

Typical Applications

Alloy L605 is frequently chosen for components requiring both high strength and wear resistance (e.g., bearing elements, furnace parts), where mechanical contact and sliding wear can occur.

Alloy 188 excels when long‑term oxidation, thermal cycling and hot corrosion resistance are the priority, especially in aerospace combustor cans and gas turbine hot sections.

## Which Alloy Should You Use?

The choice depends on your specific application requirements. Here are practical guidelines:

Choose Alloy L605 when:

- You need very high wear and galling resistance

- Strength under short‑term, high‑stress loading is critical

- Components undergo frequent mechanical contact

- Weldability and post‑fabrication annealing are part of production

Choose Alloy 188 when:

- Extended oxidation resistance in combustion gases is essential

- Long service life under thermal cycling is needed

- Reduced maintenance from hot corrosion performance is valuable

- Dimensional stability after prolonged high‑temperature exposure is required

In many general aerospace and gas turbine cases, both alloys are suitable, but the specific service environment (wear vs oxidation dominance) often determines the better option.

Internal Links — Learn More & Buy

- Visit the Alloy L605/25 product page to check the availability of plate, bar, sheet and wire.

- Explore the Alloy 188 product page for datasheets and high‑temperature performance data.

- Need help deciding? Contact NeoNickel’s technical team for tailored material selection guidance.

Both Alloy L605 and Alloy 188 are top‑tier cobalt alloys with excellent high‑temperature capabilities. While they share many strengths, the choice between them hinges on wear resistance vs oxidation/hot corrosion performance and the nature of thermal exposure in your application.

This comparison helps you quickly assess which material is best suited for your engineering and manufacturing needs, supporting your decision before you proceed to quote or purchase from NeoNickel.