Alloy 601 vs 602CA for High-Temperature Applications

When selecting a nickel alloy for high-temperature applications, two standout contenders are Alloy 601 and Alloy 602CA. Both offer excellent performance in extreme heat and aggressive atmospheres, but which is better for your application?

This article breaks down the key differences between these two high-performance materials to help buyers make an informed choice.

What is Alloy 601?

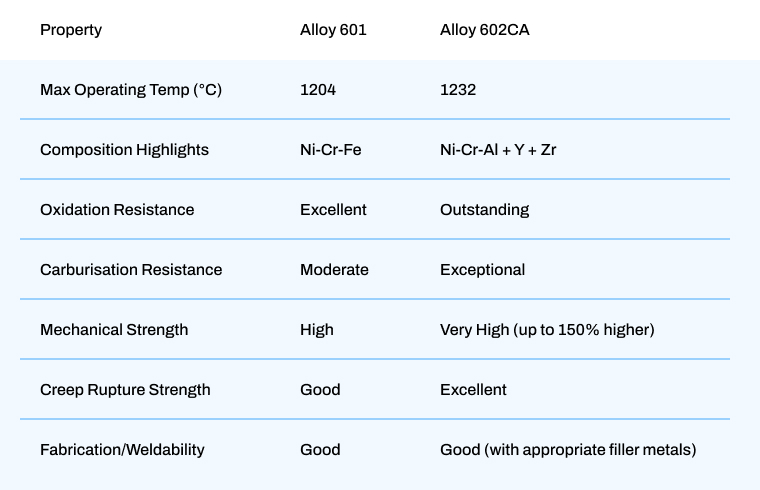

Alloy 601 is a nickel-chromium-iron alloy known for its outstanding oxidation resistance and thermal stability up to 1204°C. Its balanced composition provides excellent mechanical properties, good ductility, and reliable performance under thermal cycling.

Visit the Alloy 601 product page for more information →

What is Alloy 602CA?

Alloy 602CA is a nickel-chromium-aluminium alloy developed for even more extreme conditions. It offers exceptional oxidation resistance up to 1232°C, and its high aluminium and yttrium content promote a robust, adherent oxide layer. It also provides superior carburisation resistance and up to 150% higher creep rupture strength compared to other high-temperature alloys.

Key Chemical and Mechanical Differences

Application Suitability

Where Alloy 601 Excels

Alloy 601 is a reliable choice for thermal environments where oxidation and scaling are key concerns but carburisation is less aggressive. It's ideal for:

- Furnace components

- Heat treatment fixtures

- Industrial muffles

- Energy sector components under moderate stress

Learn more in our article: Oxidation Resistance in Alloy 601: Why It Excels in Extreme Environments.

Visit the Alloy 601 product page →

Where Alloy 602CA Outperforms

Alloy 602CA offers extended service life under high-stress, high-temperature, and carburising conditions. It is preferred in:

- Radiant tubes and furnace retorts

- Steam superheater supports

- Nuclear incineration and vitrification

- Sintering and metallurgical hardware

The inclusion of yttrium and high aluminium content ensures scale adhesion even in cyclic conditions.

Visit the Alloy 602CA product page →

Which Alloy Should You Choose?

Choose Alloy 601 if:

- Your environment involves oxidising gases but minimal carburisation

- Cost is a concern and ultra-high strength isn’t essential

- You need proven weldability and formability

Choose Alloy 602CA if:

- Your component is exposed to intense heat (up to 1232°C) and carbon-rich gases

- You need the highest possible mechanical strength

- You are working with thin-walled or load-bearing components over long durations

For marine or chloride-rich environments, you may want to consider Alloy 625 as a corrosion-resistant alternative.

Summary: Alloy 601 vs 602CA

Both alloys perform impressively in extreme temperatures, but Alloy 602CA delivers a higher level of protection and strength under more aggressive thermal and chemical environments. Alloy 601 remains a solid and cost-effective performer for many thermal oxidation applications.

Ultimately, the right choice depends on your specific service conditions, required mechanical performance, and design priorities.

Need Help Choosing?

At NeoNickel, we supply both Alloy 601 and Alloy 602CA in a range of forms including plate, bar, sheet, and wire. Our technical team is available to help you select the right material for your application.

Get in touch with NeoNickel for expert guidance and product enquiries.